Technologies

Innovative Technologies Tailored to your vision

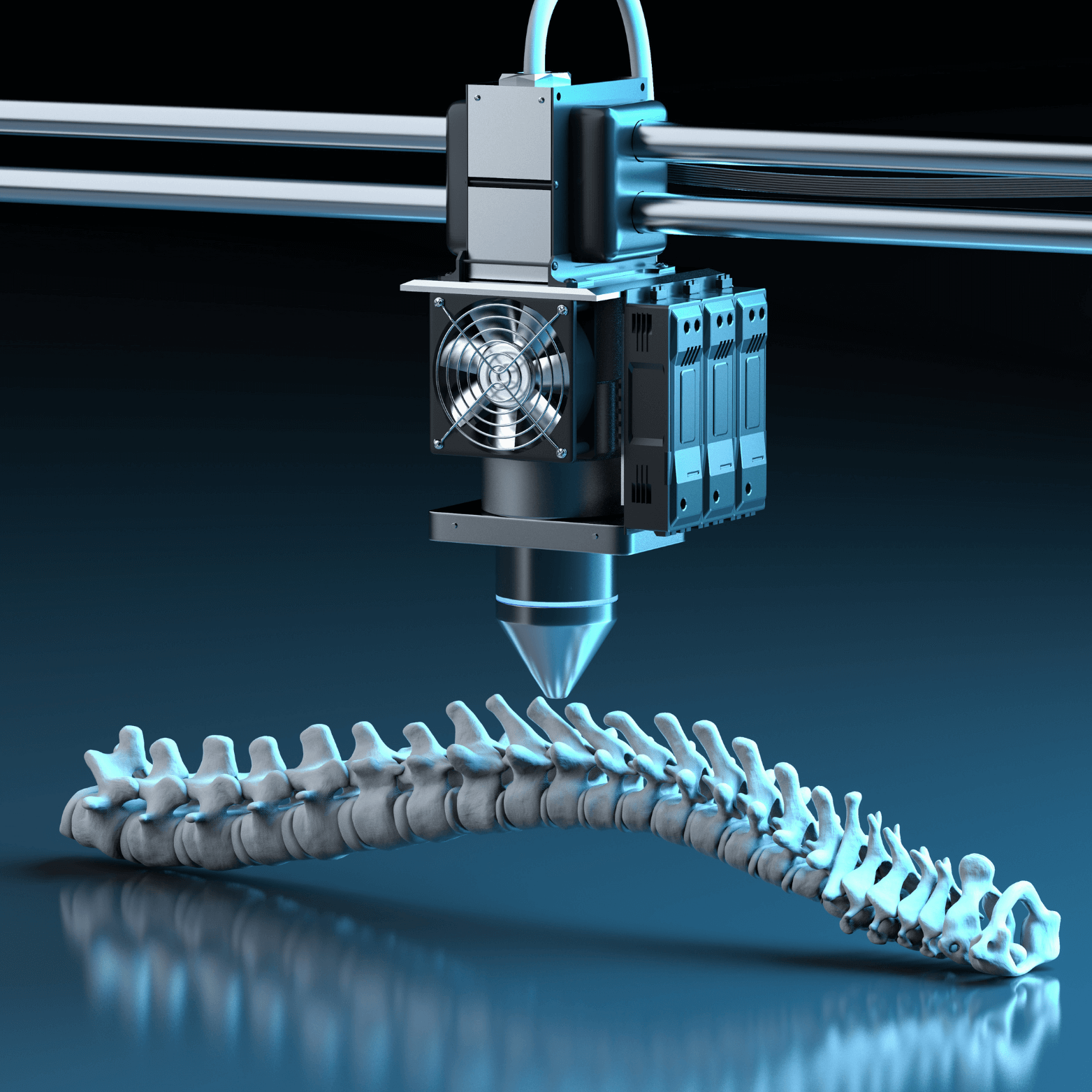

Explore our extensive range of technology services, meticulously designed around plastics, metals, rubber, and fabric – the core materials that we work with daily. Below, you will find a curated list of our most utilized technology services. Click on any service that piques your interest, and a succinct text box will appear, providing more details. Shoney Scientific Inc is also capable of several other services such as 3D Printing, Product Validation, Engineering, Complete Assembly and much more which you can see in the Other Services section. With our extensive list of technologies Shoney Scientific Inc. will become your one stop shop to creating a high-quality customized product that stands high above the rest.

Book a meeting today to begin your product development journey with Shoney Scientific Inc. – where technology meets innovation.

Plastics

- Injection Molding

- Extrusion

- Thermoforming

- Blow Molding

- Dip Molding

- RF Welding

- Tipping

- Surface Coating

- Punching

Injection Molding is a highly versatile manufacturing process used to produce intricate and precise plastic components. In this process, molten plastic is injected into a mold cavity, where it cools and solidifies to form the desired shape. Injection molding is a cost-effective solution for the mass production of a diverse range of plastic products.

Extrusion is a manufacturing process used to create plastic parts made of consistent cross-sectional profiles. Plastic material is melted and forced through a die to produce a continuous shape, such as tubing, pipes, or other items. Once the material is cooled, the product is cut to its desired lengths. Extrusion is a process that is cost-effective and offers the ability to produce lengthy components with uniformity.

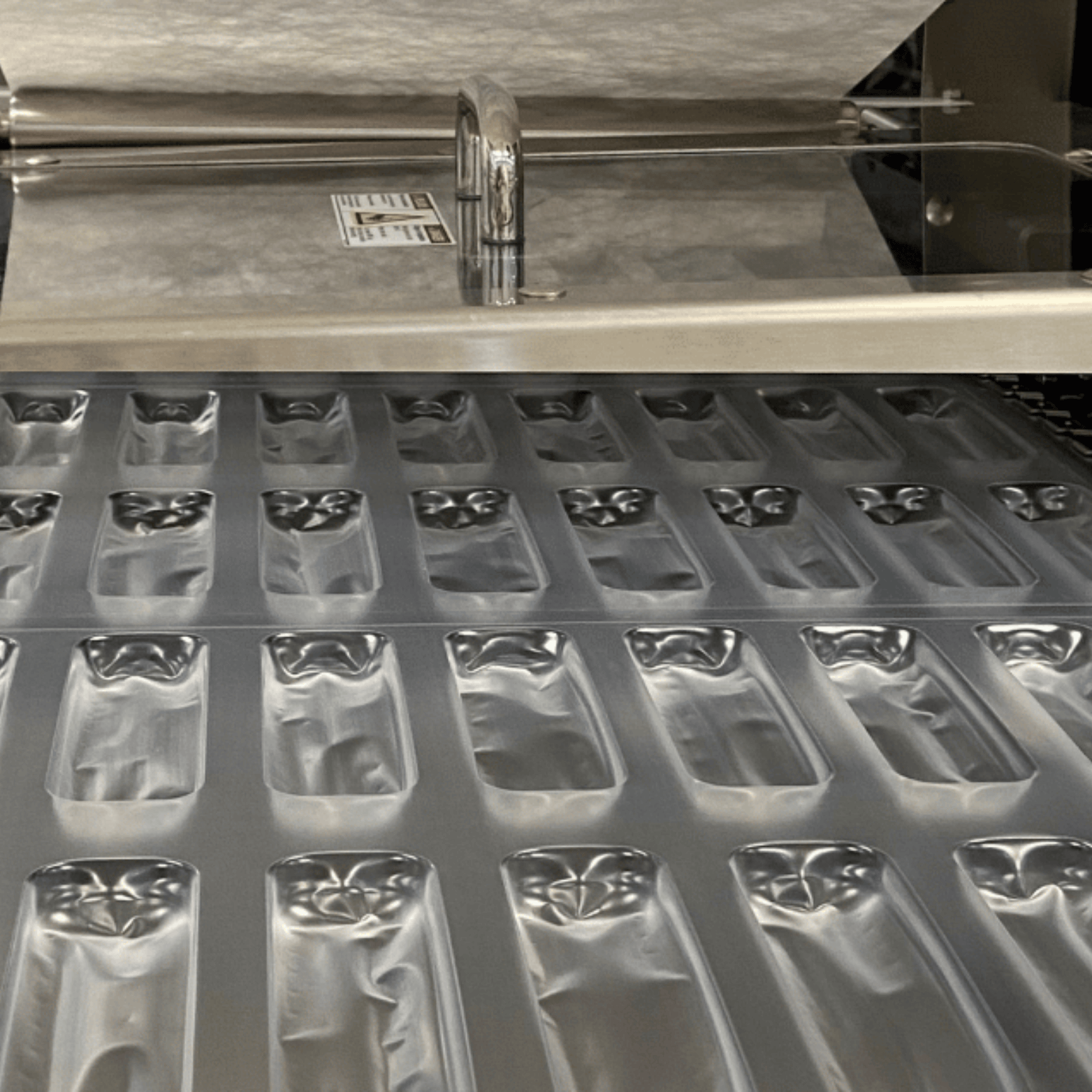

Thermoforming is a versatile manufacturing process employed to shape plastic sheets into a wide range of products. The process involves heating a plastic sheet until it becomes pliable, then forming it into a specific shape using a mold or pattern. Once the plastic cools and solidifies, the desired product is obtained. This method is cost-effective and allows for rapid production capabilities and intricate designs.

Blow molding is a sophisticated manufacturing process widely used to produce hollow plastic products, ranging from bottles and containers to automotive components. This method involves shaping molten plastic into a hollow form by blowing air into a mold. The plastic material then takes the shape of the mold as it expands, creating a seamless and lightweight final product. This procedure allows for efficiency in producing high volumes of consistent, durable, and cost-effective plastic containers.

Dip Molding is a specialized plastic manufacturing process that is ideal for creating seamless, thin-walled, and flexible plastic products. A metal mold is immersed into a liquid polymer, such as PVC, latex, or plastisol. The mold is then gradually withdrawn, and the liquid coating adheres to the surface. Once the coated mold is exposed to heat, the polymer undergoes curing, which forms the solid and resilient layer that takes the shape of the mold. This process is used to produce uniform, high-quality, and customizable products, especially for grips, caps, handles, and medical devices.

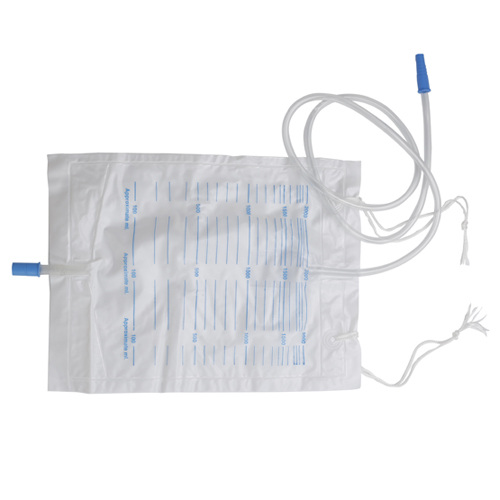

RF (Radio Frequency) welding is a sophisticated plastic joining technique that is used to create strong and durable bonds in thermoplastic material. In RF welding two pieces of plastic are placed between electrodes where a RF generator emits high-frequency electromagnetic energy. This will cause the molecules in the plastic to vibrate, which generates heat. The heated plastic softens and fuses, creating a seamless and robust bond when pressure is applied. RF Welding is well-suited for creating airtight and watertight seals making it perfect for inflatable products, medical bags, and automotive components.

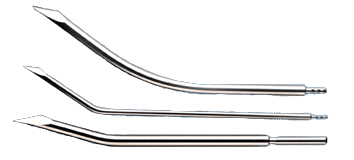

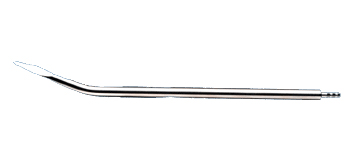

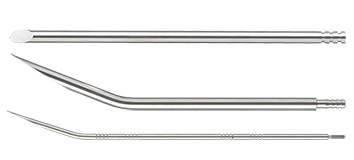

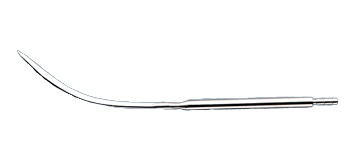

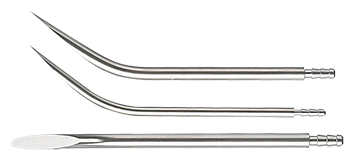

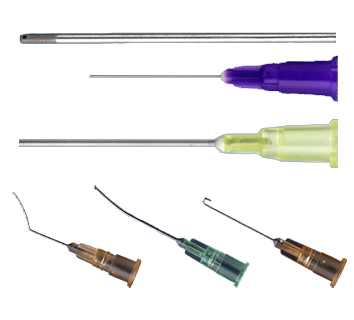

Tipping is a specialized process where a specific component, often a tip or cap is added to a product to improve functionality, aesthetics, or safety features of the product. The process involves carefully attaching or incorporating the tipping component on the main structure of the product. This process requires precision and attention to detail.

Surface Coating is a process used to enhance the aesthetics, durability, and performance of a product. We have several types of coatings available, and we would love to go over your product and determine the best coatings that fit your project requirements.

In the context of plastic products, punching refers to a process involving the use of a punch and die to cut or shape materials, typically plastic sheets, or films. This method is commonly known as die-cutting or punching and is a versatile technique employed to create precise and intricate shapes in plastics. A punch is a tool that cuts through the material and a die provides the shape or contour.

Punching is often used in the production of various plastic items, including packaging materials, gaskets, labels, and other precision components.

Plastics

- Injection Molding

- Extrusion

- Thermoforming

- Blow Molding

- Dip Molding

- RF Welding

- Tipping

- Surface Coating

- Punching

Injection Molding is a highly versatile manufacturing process used to produce intricate and precise plastic components. In this process, molten plastic is injected into a mold cavity, where it cools and solidifies to form the desired shape. Injection molding is a cost-effective solution for the mass production of a diverse range of plastic products.

Extrusion is a manufacturing process used to create plastic parts made of consistent cross-sectional profiles. Plastic material is melted and forced through a die to produce a continuous shape, such as tubing, pipes, or other items. Once the material is cooled, the product is cut to its desired lengths. Extrusion is a process that is cost-effective and offers the ability to produce lengthy components with uniformity.

Thermoforming is a versatile manufacturing process employed to shape plastic sheets into a wide range of products. The process involves heating a plastic sheet until it becomes pliable, then forming it into a specific shape using a mold or pattern. Once the plastic cools and solidifies, the desired product is obtained. This method is cost-effective and allows for rapid production capabilities and intricate designs.

Blow molding is a sophisticated manufacturing process widely used to produce hollow plastic products, ranging from bottles and containers to automotive components. This method involves shaping molten plastic into a hollow form by blowing air into a mold. The plastic material then takes the shape of the mold as it expands, creating a seamless and lightweight final product. This procedure allows for efficiency in producing high volumes of consistent, durable, and cost-effective plastic containers.

Dip Molding is a specialized plastic manufacturing process that is ideal for creating seamless, thin-walled, and flexible plastic products. A metal mold is immersed into a liquid polymer, such as PVC, latex, or plastisol. The mold is then gradually withdrawn, and the liquid coating adheres to the surface. Once the coated mold is exposed to heat, the polymer undergoes curing, which forms the solid and resilient layer that takes the shape of the mold. This process is used to produce uniform, high-quality, and customizable products, especially for grips, caps, handles, and medical devices.

RF (Radio Frequency) welding is a sophisticated plastic joining technique that is used to create strong and durable bonds in thermoplastic material. In RF welding two pieces of plastic are placed between electrodes where a RF generator emits high-frequency electromagnetic energy. This will cause the molecules in the plastic to vibrate, which generates heat. The heated plastic softens and fuses, creating a seamless and robust bond when pressure is applied. RF Welding is well-suited for creating airtight and watertight seals making it perfect for inflatable products, medical bags, and automotive components.

Tipping is a specialized process where a specific component, often a tip or cap is added to a product to improve functionality, aesthetics, or safety features of the product. The process involves carefully attaching or incorporating the tipping component on the main structure of the product. This process requires precision and attention to detail.

Surface Coating is a process used to enhance the aesthetics, durability, and performance of a product. We have several types of coatings available, and we would love to go over your product and determine the best coatings that fit your project requirements.

In the context of plastic products, punching refers to a process involving the use of a punch and die to cut or shape materials, typically plastic sheets, or films. This method is commonly known as die-cutting or punching and is a versatile technique employed to create precise and intricate shapes in plastics. A punch is a tool that cuts through the material and a die provides the shape or contour.

Punching is often used in the production of various plastic items, including packaging materials, gaskets, labels, and other precision components.

Rubber

Compression Molding is a widely used manufacturing process for shaping rubber and other elastomers into various products. It involves the use of heat and pressure to mold and cure rubber compounds and create objects with specific shapes and properties. Compression molding is particularly suitable for producing medium to large volumes of rubber products with consistent quality. Compression Molding is cost-effective, versatile as it can accommodate a wide range of rubber formulations and provides consistent and reliable results.

Transfer molding is a manufacturing process designed for shaping rubber and elastomeric materials into intricate and high-precision products. This method seamlessly combines the advantages of compression molding and injection molding and offers a unique set of benefits. Transfer molding is used because of its precision in achieving intricate shapes and designs, uniformity in product dimensions and properties, efficiency, and versatility for diverse applications.

LSR Molding stands for Liquid Silicone Rubber molding which is a specialized process used to produce silicone rubber parts and components. Liquid silicone rubber is a high-purity platinum-cured silicone material that offers various benefits including flexibility, resistance, and biocompatibility. LSR molding is particularly suitable for applications where precision, durability, and the unique properties of silicone are crucial. LSR is commonly used in industries such as healthcare, automotive, electronics, and consumer goods where the unique properties of silicone rubber are advantageous.

Compounding, in the context of manufacturing and materials, refers to the process of combining different raw materials or ingredients to create a new material with specific properties. The process is commonly used in various industries, including plastics, rubber, pharmaceuticals, and food processing. The goal of compounding is to achieve a material or product with specific characteristics that may not be present in individual raw materials alone and allows manufacturers to tailor their material.

In manufacturing, formulating applies to creating specific blends of raw materials to produce products with predefined characteristics. This is common in the formulation of polymers, plastics, and other materials based on requirements of the product.

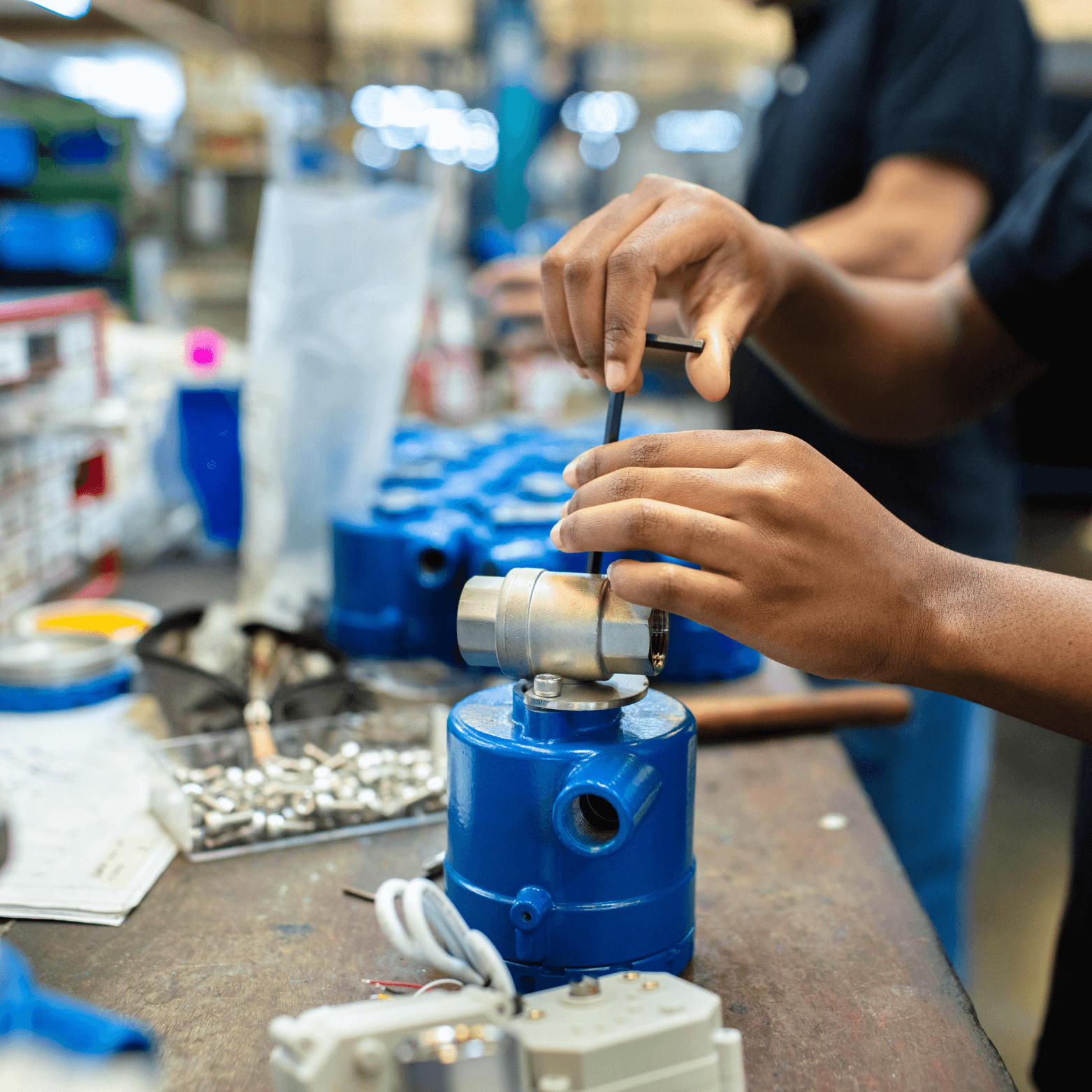

Metal Working

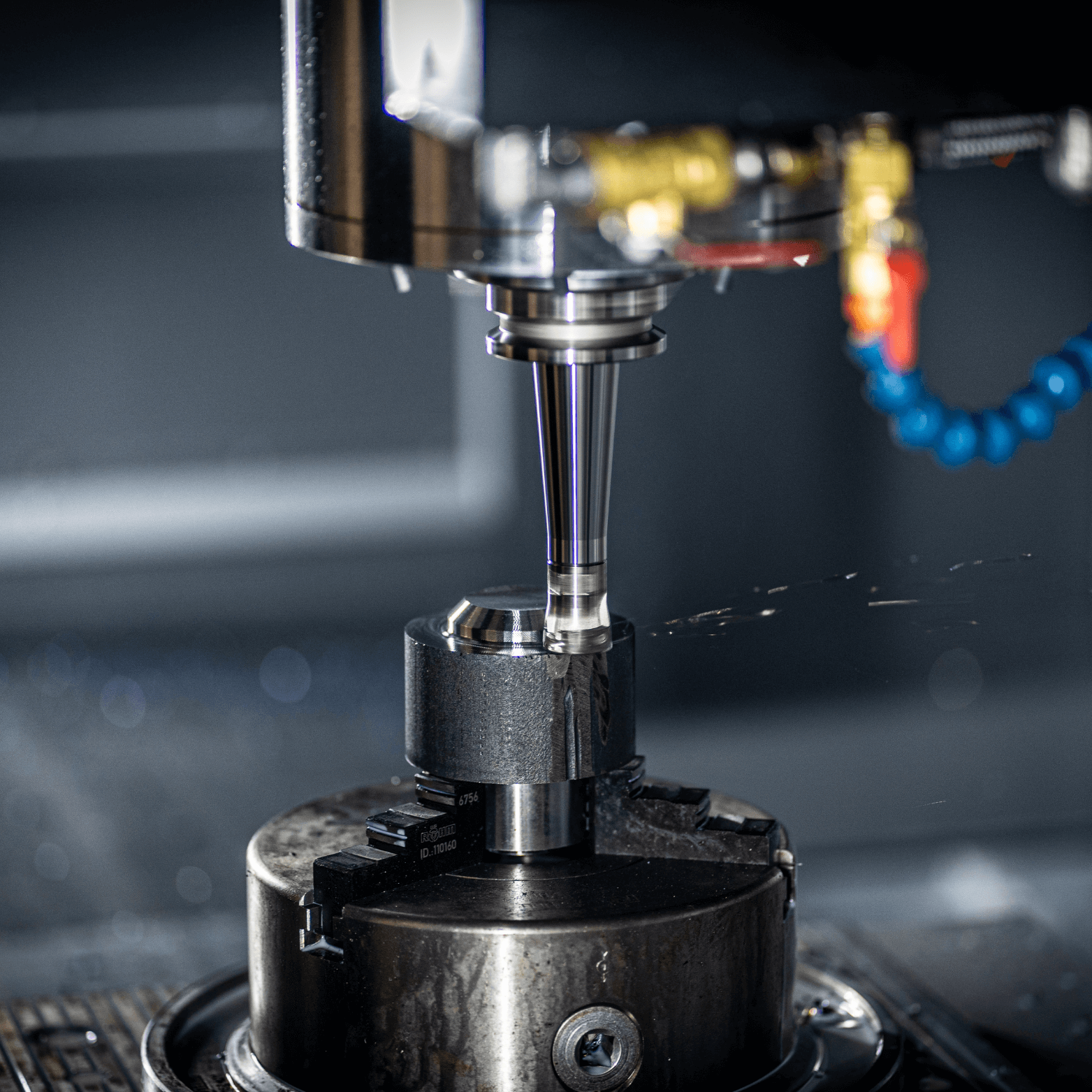

Machining

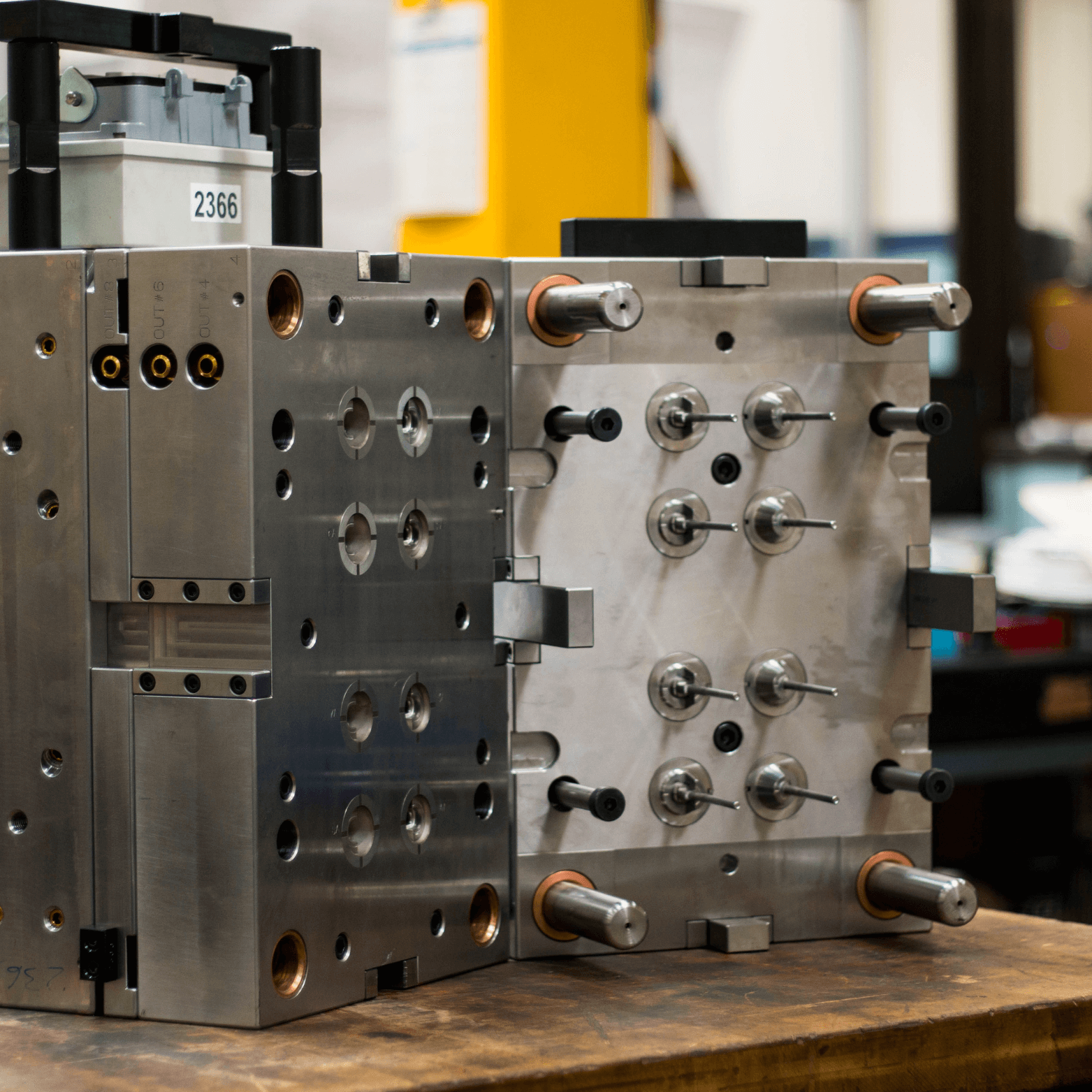

Mold/Tool Building

Surface Grinding

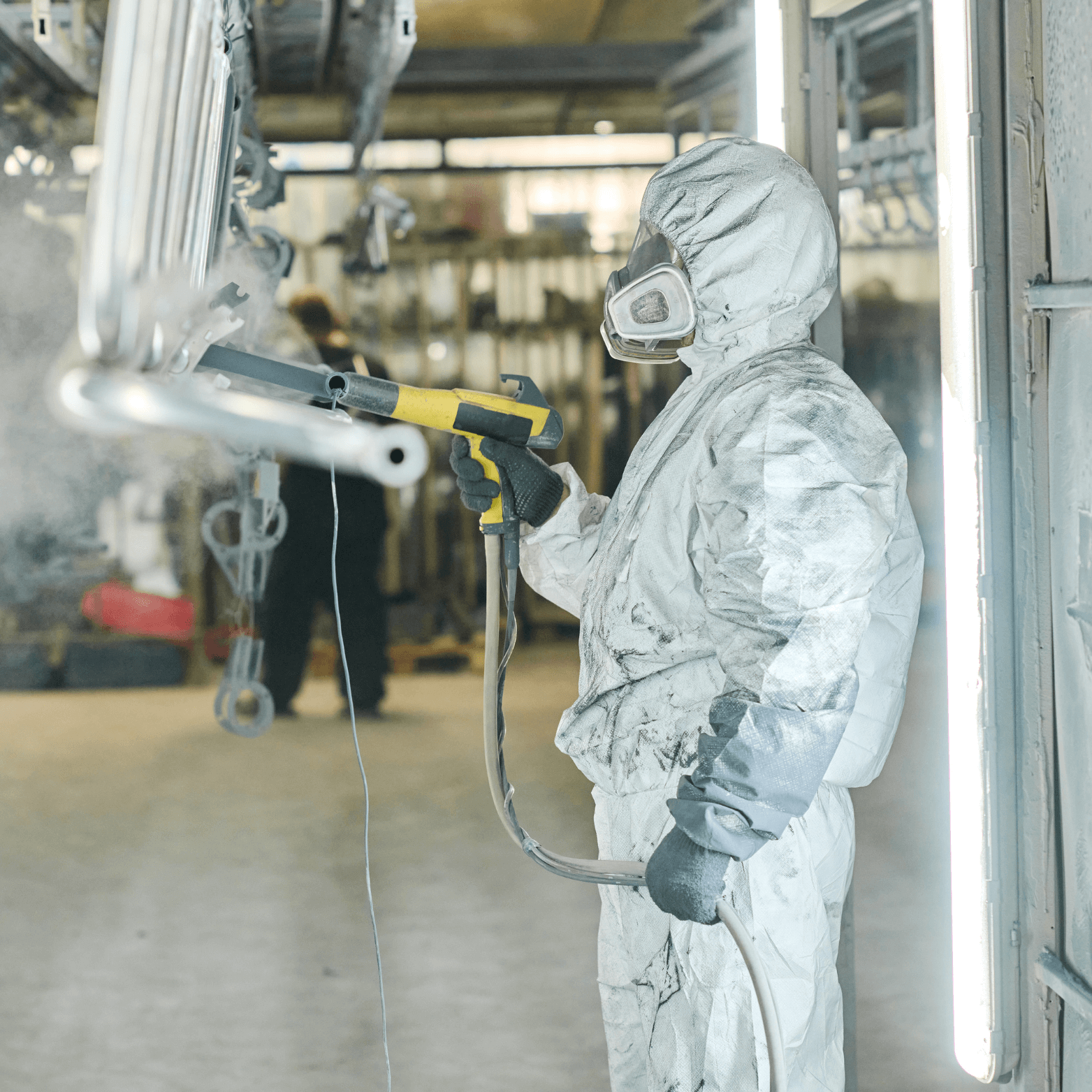

Sandblasting

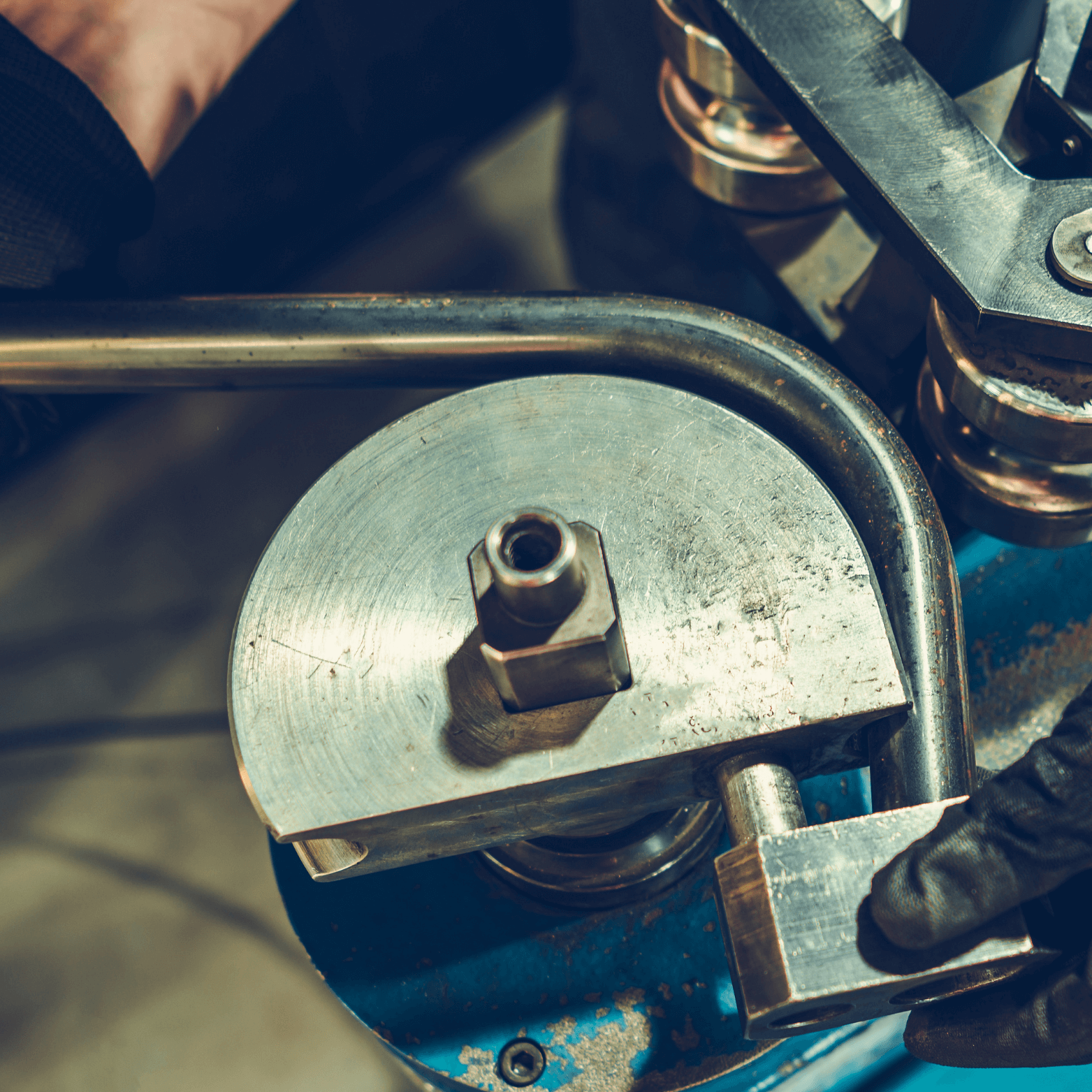

Pipe Bending

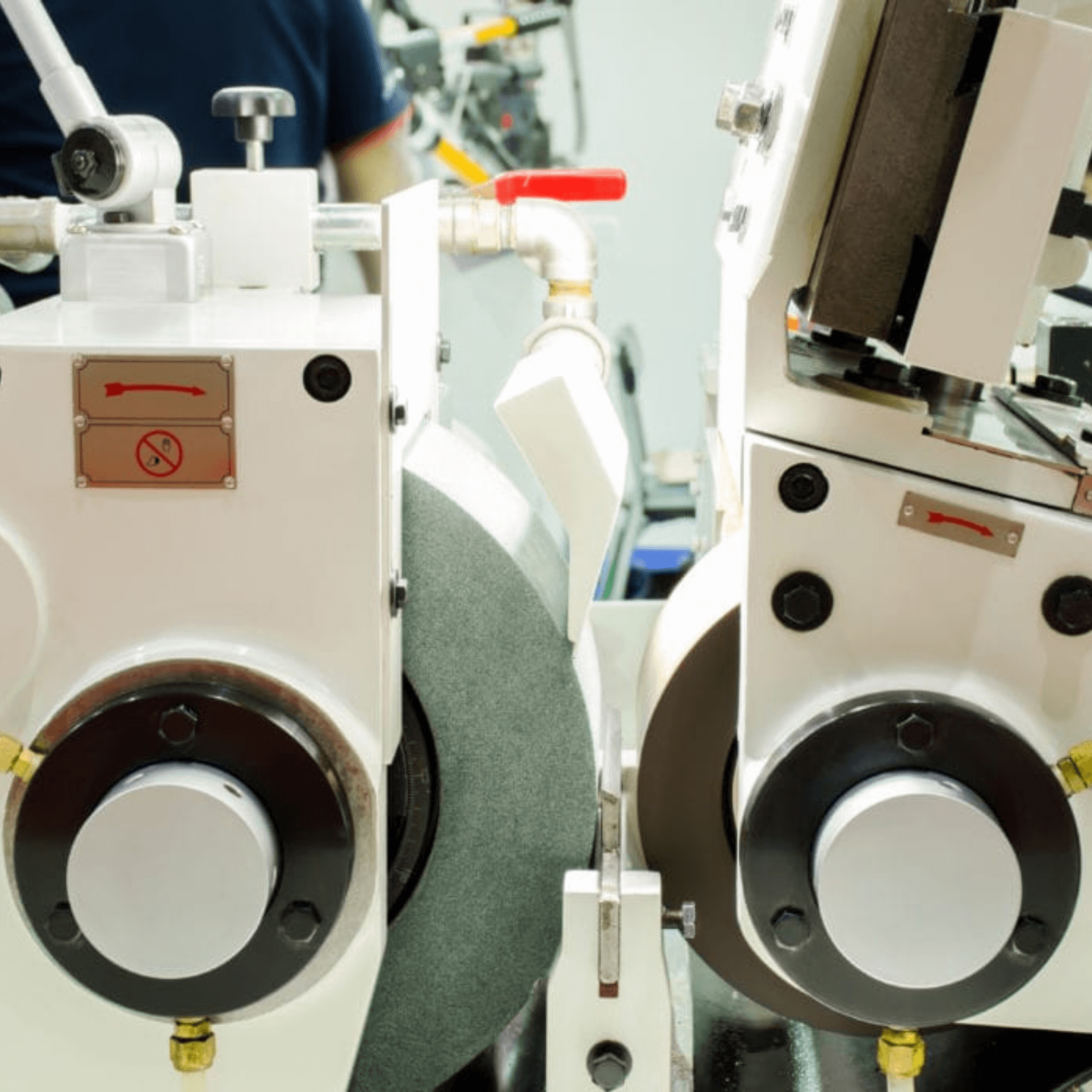

Centerless Grinding

Swaging

Powder Coating

Plating

Chemical Etching

Electrochemical Polishing

Chemical Polishing

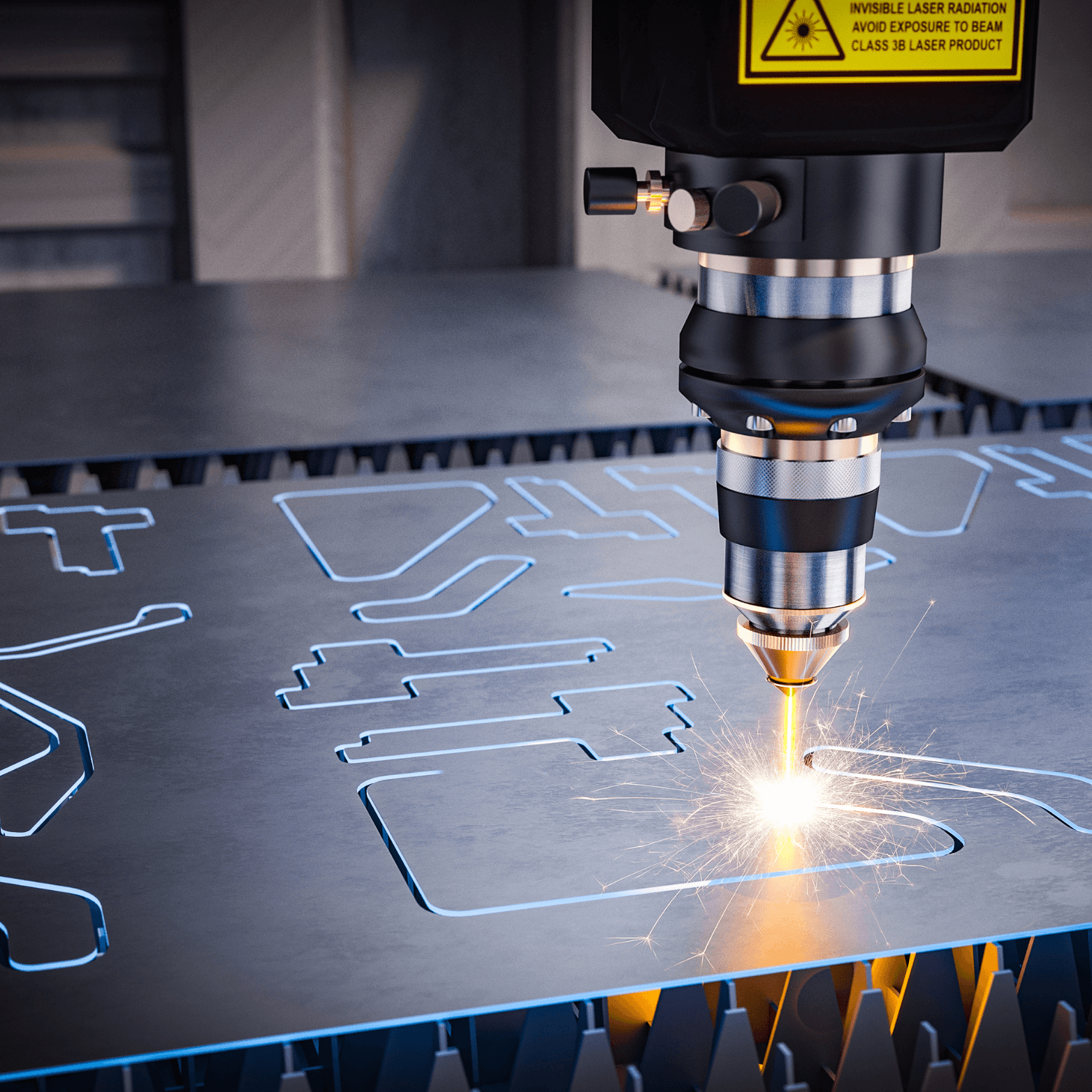

Laser Marking

Stamping

Titanium Coating

Others

Bonding

Nonwoven Fabric Processing

Complete Packaging Services

Form, Fill, and Seal (FFS)

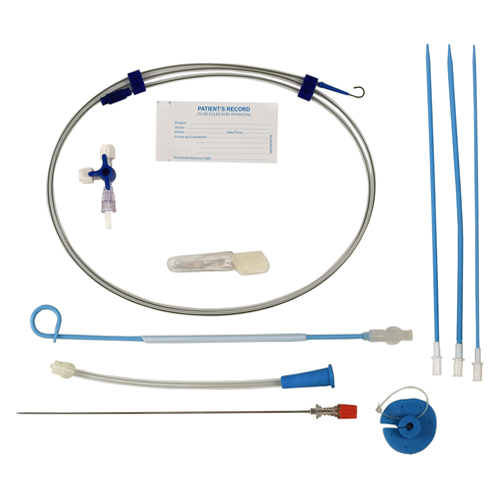

Complete Assembly

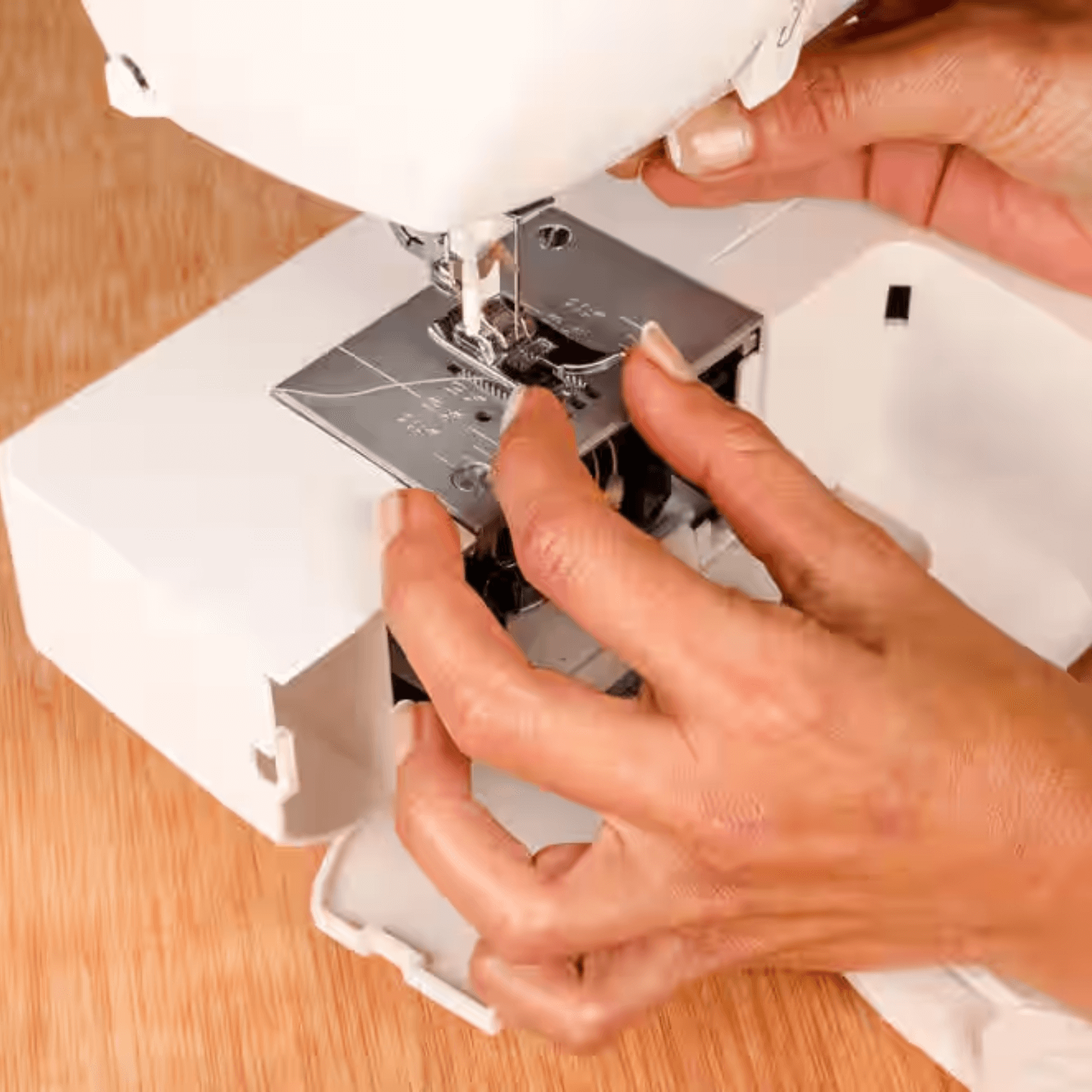

Complete Sewing

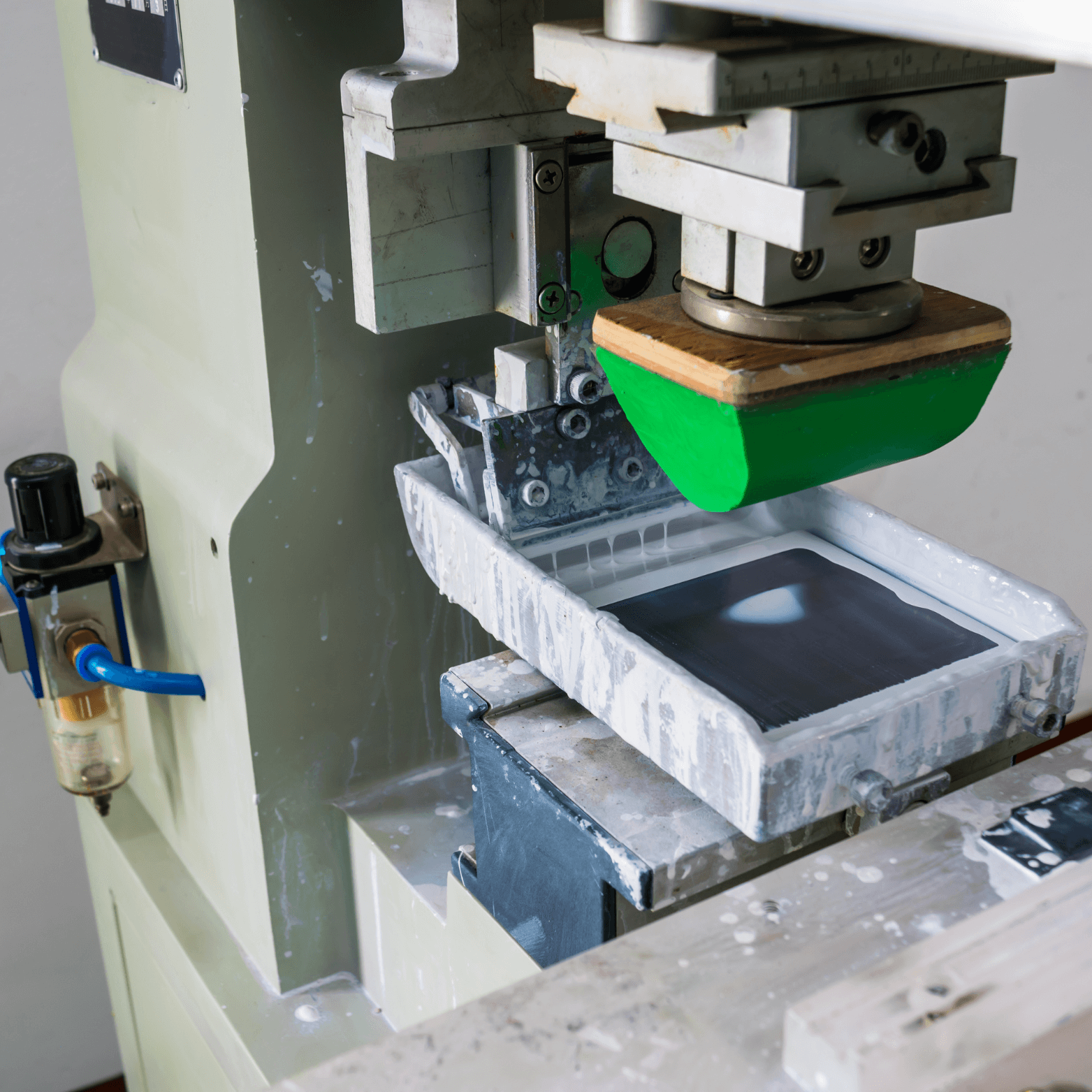

Pad Printing

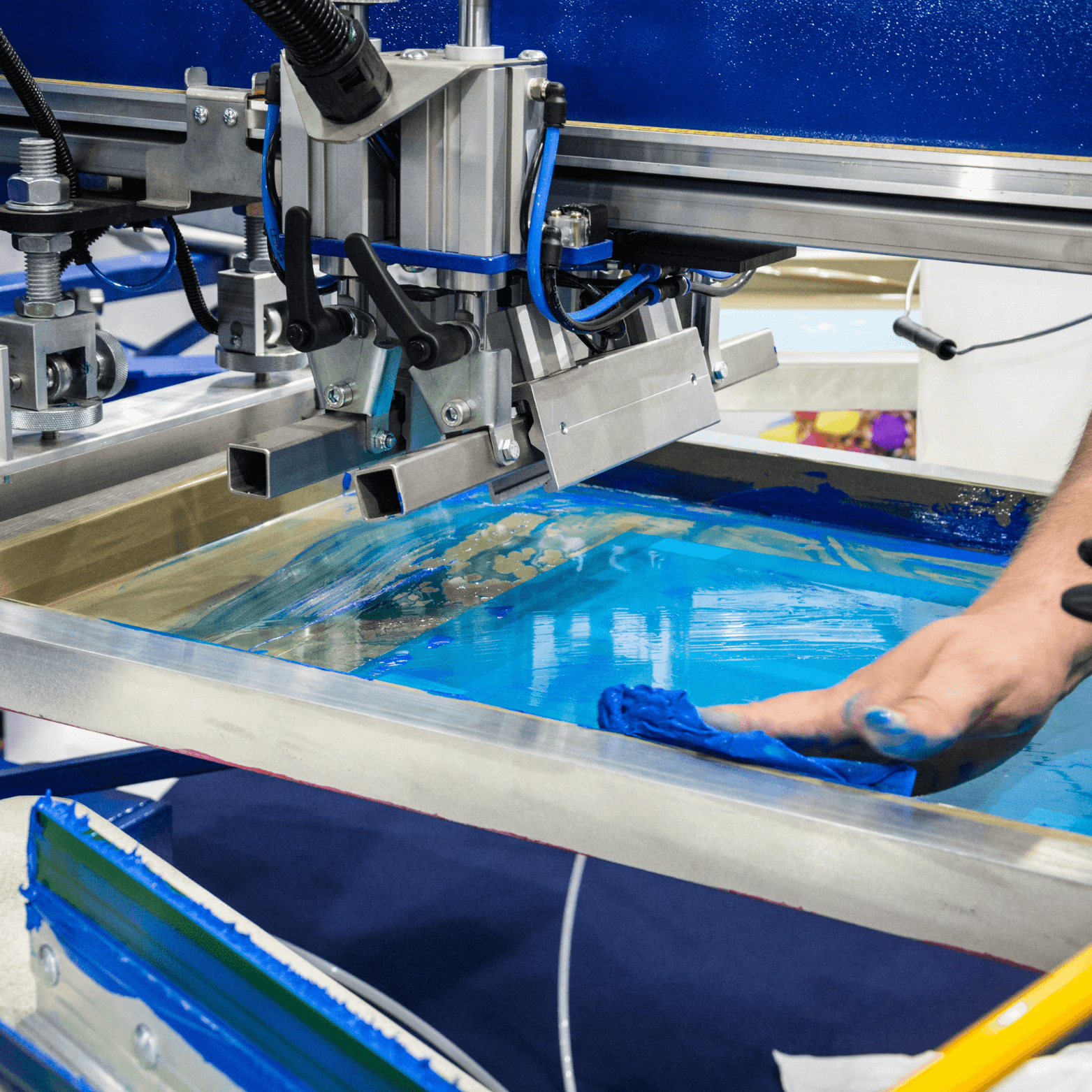

Silk Screening

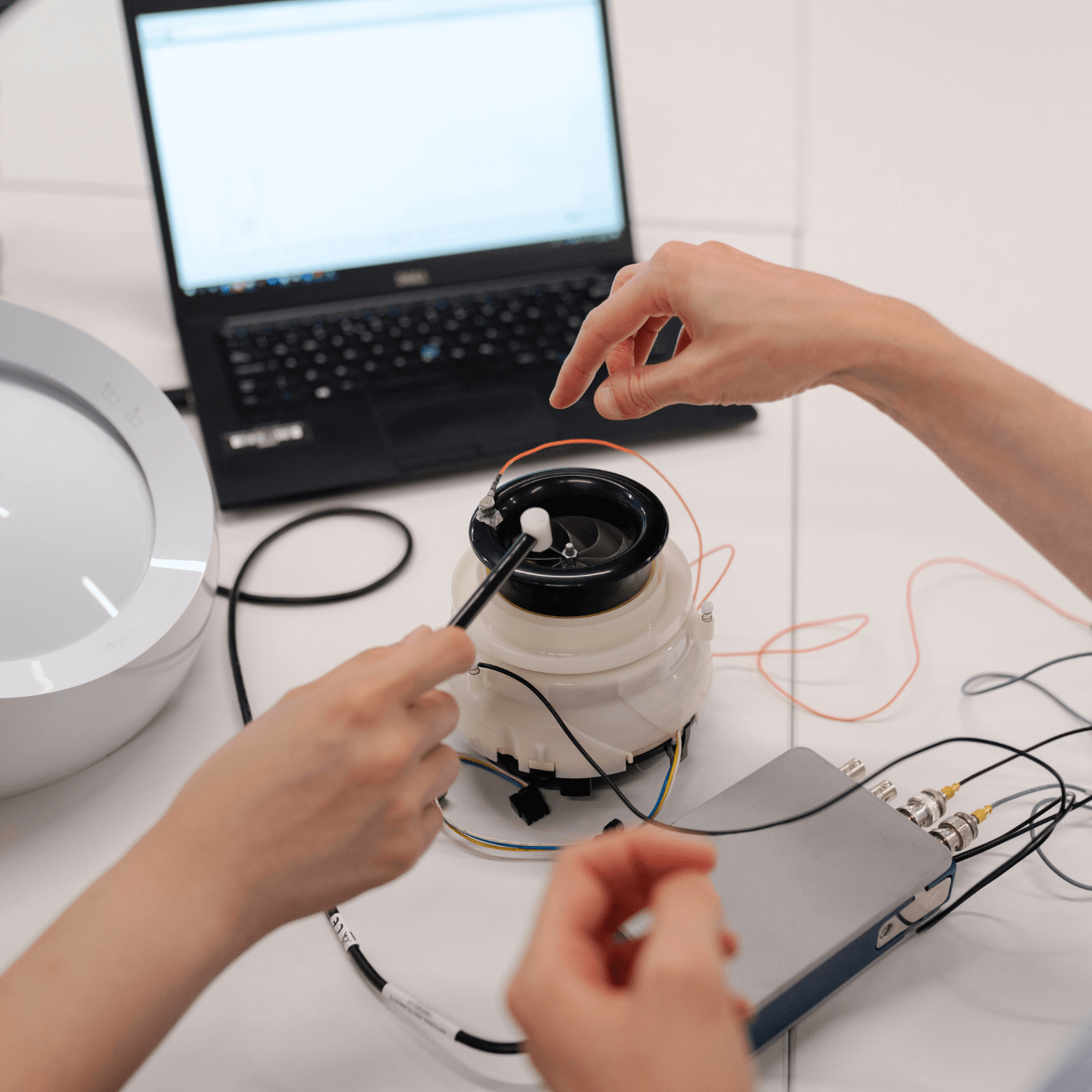

Process Validation

EtO Sterilization

Product Engineering

Prototyping

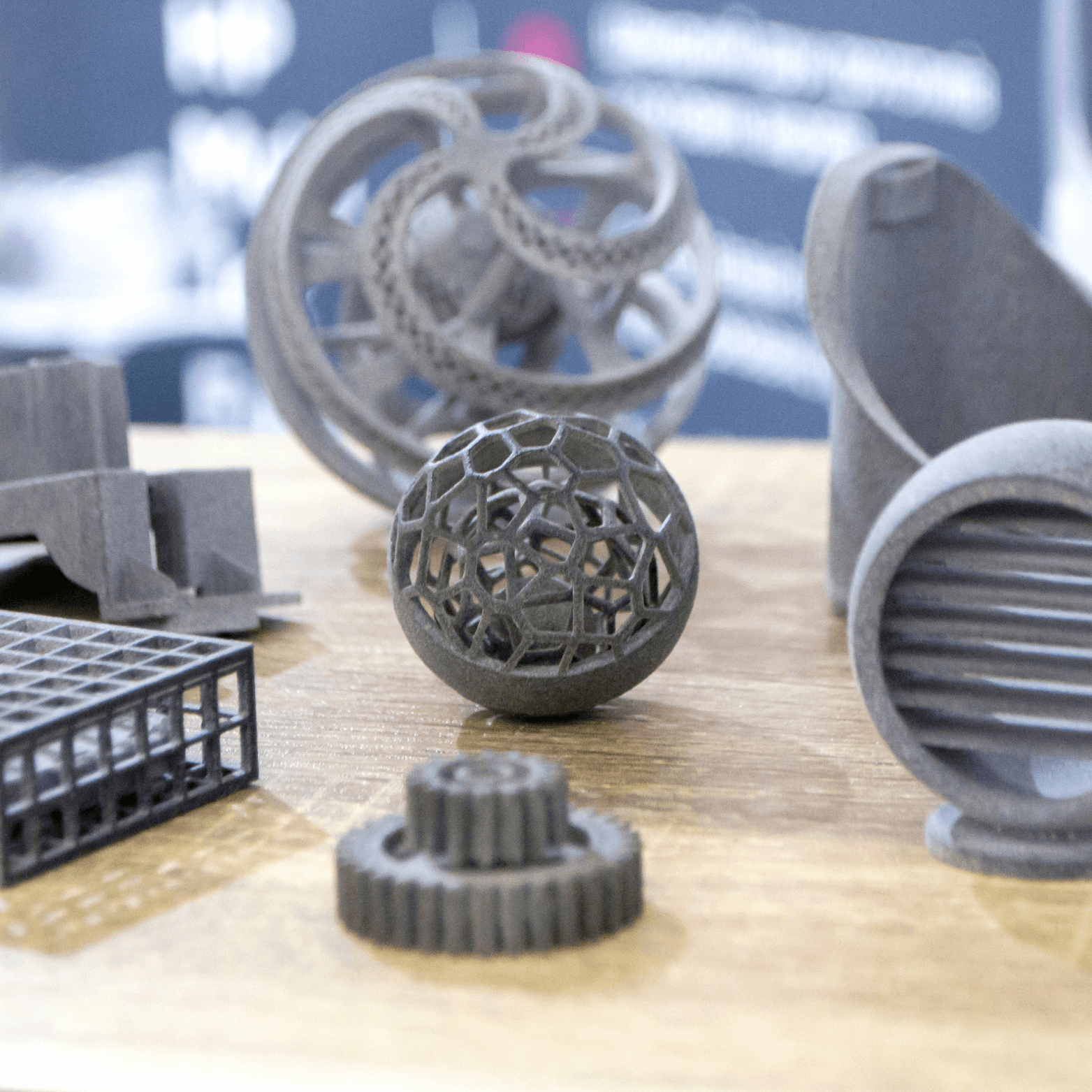

3D Printing

Compression Molding Machine

Plastic Injection Molding Machine

Rubber Compounding Mixer Machine